I'm no hand knitter, but I wanted to try knitting a seamless sweater in the round. There is a good tutorial available at Knitpicks.com, complete with videos and handouts. I used bulky yarn because I can't tolerate the snail's pace that smaller yarns knit at. It went very quickly, about two weeks, and I didn't make all that many mistakes. Knitting round means no purling which speeds things up exponentially. I made some miscalculations about the amount of curl at the hem, but otherwise it turned out quite well. The yarn is Wool of the Andes bulky in redwood, which was being discontinued when I purchased it.

I really like the appearance of raglan seams by strategically placing the decreases. This project was a lot of fun and I would do it again (with bulky yarn).

Sunday, July 3, 2011

Neckline lessons learned

This is a pair of drop shoulder work sweaters I made using the pattern in the book that came with the ISM. This is the first one I made:

On a knitting machine, it is not necessary to bind off stitches that will become part of the neckband. However, I learned from making this sweater that it is extremely desirable. The weight of the sleeves pulls the shoulders outwards, stretching the neck out as wide as it will go. The bind off around the neck band is sloppy too. The rest of the sweater turned out ok.

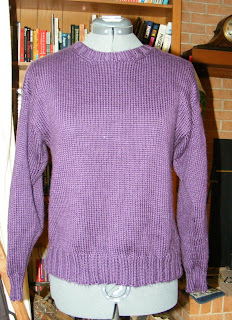

There were several wonderful colors at the store when I bought the blue yarn, so I bought this purple yarn as well and made this one:

This one, I did bind off the back neck edge and bound off the band a little tighter. The band bind off is almost too tight to fit over my head. I also thought the blue one was a bit loose and made some adjustments to the sleeves and body, resulting in sleeves that are too tight. In fact one sleeve was so tight that I took the sweater apart after finishing and remade it.

Maybe the neckline solution is to bind off both front and back and not bind off the neckband tightly.

Unfortunately, the yarn is Simply Soft, so both sweaters are hairy and fading after just a couple of washes.

On a knitting machine, it is not necessary to bind off stitches that will become part of the neckband. However, I learned from making this sweater that it is extremely desirable. The weight of the sleeves pulls the shoulders outwards, stretching the neck out as wide as it will go. The bind off around the neck band is sloppy too. The rest of the sweater turned out ok.

There were several wonderful colors at the store when I bought the blue yarn, so I bought this purple yarn as well and made this one:

This one, I did bind off the back neck edge and bound off the band a little tighter. The band bind off is almost too tight to fit over my head. I also thought the blue one was a bit loose and made some adjustments to the sleeves and body, resulting in sleeves that are too tight. In fact one sleeve was so tight that I took the sweater apart after finishing and remade it.

Maybe the neckline solution is to bind off both front and back and not bind off the neckband tightly.

Unfortunately, the yarn is Simply Soft, so both sweaters are hairy and fading after just a couple of washes.

Labels:

knitting

Another lousy sweater

I wrote this pattern from scratch for the Bond using Maggie Righetti's book Sweater Design in Plain English. Although this book is long, it doesn't say much and takes a long time and a convoluted path to say what it does. She expects you to work through all the lessons in textbook fashion, adding a little more information each chapter. I think it'd be much more useful if she just isolated the techniques and described them, and then told you how to put them together.

Even though I made plain and ribbing swatches and put ease in my measurements, things came out the wrong size. The waist ribbing was supposed to be deeper, the neck opening was way too big, the sleeves are too tight, you name it. The baby weight yarn was borderline too fine for the Bond and too thick for the standard gauge, and the result was incredibly messy decreases along the neck edge and armholes. Doesn't it look great on the dummy, though?

Even though I made plain and ribbing swatches and put ease in my measurements, things came out the wrong size. The waist ribbing was supposed to be deeper, the neck opening was way too big, the sleeves are too tight, you name it. The baby weight yarn was borderline too fine for the Bond and too thick for the standard gauge, and the result was incredibly messy decreases along the neck edge and armholes. Doesn't it look great on the dummy, though?

Labels:

knitting

Saturday, July 2, 2011

Recreating HK twisted stitches on a Bond

Sometime last year, I got a Knitpicks catalog that featured this sweater to sell their line of tweeds:

I fell in love with the sweater, but the yarn was so expensive. After months and months of deliberating, I gave in and bought their yarn and located a used copy of the book. The design is done in twisted stitches. Not being a hand knitter, though, I was not sure how to accomplish this on a machine. After doing some practice knitting using hand needles, I figured out what to do. It's much easier to achieve the same effect on a machine than by hand because you can see the design better so it's easier to know how to pass the stitches over one another. At least to me it is. Plus, hand knitters have to perform different operations to achieve the same effect depending on whether a purl or knit side is being worked. However, this is one instance where machine knitting is not necessarily faster than hand knitting.

Due to the nature of reforming stitches, you will be working your pattern one row below the row just knitted. That is to say, if row 3 has just been knitted, you will be looking at row 2 on the chart for the patterning. It's confusing at first, but think about how the loops on the needles can't be reformed in any meaningful way. There is no purl bump to be manipulated, so they must be formed a row behind. Also, because the middle of the pattern repeats in a different number of rows than that on either side, I found it enormously helpful to plot the full chart out as an excel spreadsheet, with all the pattern repeats, increases, and decreases in their appropriate places so I don't have to try to keep up with when to decrease, what row of which section of pattern to use, etc.

To get your basic twisted knit stitch, you need a seed stitcher. This is a latch tool with latches at both ends. When you reform your stitch, rotate the seed stitcher 180 degrees then proceed as normal. I don't know if this is technically the equivalent of an HK twisted stitch, but it looks like one and that's good enough for me. If the pattern calls for the stitches to be rearranged on the hand knitting needles, proceed on the machine as if you were forming cables. First, twist the stitches as previously described. Then, with your transfer tool, have the stitches trade places. You can do a one by one switch, a two by one switch, and maybe more but that's all I've done. You must pay attention to which stitch is rehung first. Stitches that cross over must be rehung last.

In this photo, the top row has just been knitted and the stitches from the previous row will now be reformed. In the cable design, a two stitch "vine" criscrosses over a one stitch "vine" up the work. You won't always be crossing twisted stitches. On the left side of the photo above, you can see a little bit of the center motif. The knit stitches appear to zigzag up the work. This is also a one by one cable but only one stitch is twisted. Simply twist one stitch and have it trade needles with a plain stitch.

It is extremely slow work. I've been working on and off this one section since Easter and have only done 68 rows. In between doing all that, I made two more sweaters on a different machine without doing manual patterning.

I fell in love with the sweater, but the yarn was so expensive. After months and months of deliberating, I gave in and bought their yarn and located a used copy of the book. The design is done in twisted stitches. Not being a hand knitter, though, I was not sure how to accomplish this on a machine. After doing some practice knitting using hand needles, I figured out what to do. It's much easier to achieve the same effect on a machine than by hand because you can see the design better so it's easier to know how to pass the stitches over one another. At least to me it is. Plus, hand knitters have to perform different operations to achieve the same effect depending on whether a purl or knit side is being worked. However, this is one instance where machine knitting is not necessarily faster than hand knitting.

Due to the nature of reforming stitches, you will be working your pattern one row below the row just knitted. That is to say, if row 3 has just been knitted, you will be looking at row 2 on the chart for the patterning. It's confusing at first, but think about how the loops on the needles can't be reformed in any meaningful way. There is no purl bump to be manipulated, so they must be formed a row behind. Also, because the middle of the pattern repeats in a different number of rows than that on either side, I found it enormously helpful to plot the full chart out as an excel spreadsheet, with all the pattern repeats, increases, and decreases in their appropriate places so I don't have to try to keep up with when to decrease, what row of which section of pattern to use, etc.

To get your basic twisted knit stitch, you need a seed stitcher. This is a latch tool with latches at both ends. When you reform your stitch, rotate the seed stitcher 180 degrees then proceed as normal. I don't know if this is technically the equivalent of an HK twisted stitch, but it looks like one and that's good enough for me. If the pattern calls for the stitches to be rearranged on the hand knitting needles, proceed on the machine as if you were forming cables. First, twist the stitches as previously described. Then, with your transfer tool, have the stitches trade places. You can do a one by one switch, a two by one switch, and maybe more but that's all I've done. You must pay attention to which stitch is rehung first. Stitches that cross over must be rehung last.

In this photo, the top row has just been knitted and the stitches from the previous row will now be reformed. In the cable design, a two stitch "vine" criscrosses over a one stitch "vine" up the work. You won't always be crossing twisted stitches. On the left side of the photo above, you can see a little bit of the center motif. The knit stitches appear to zigzag up the work. This is also a one by one cable but only one stitch is twisted. Simply twist one stitch and have it trade needles with a plain stitch.

It is extremely slow work. I've been working on and off this one section since Easter and have only done 68 rows. In between doing all that, I made two more sweaters on a different machine without doing manual patterning.

Labels:

knitting

Friday, July 1, 2011

A typical scene in my kitchen

This photo is representative of my kitchen at any given time:

Foreground: valve lapping in progress. Background: extended Bond machine on table and project in chair

Foreground: valve lapping in progress. Background: extended Bond machine on table and project in chair

Tree sweater from custom punchcard

This sweater is the result of the custom punchcard I showed in an earlier post. I believe it was my first attempt at drawing a custom knit contour pattern as well.

As you can see, there were some issues.

Aside from a botched collar, there are many patterning errors. I might have left it alone despite the patterning flaws, but the collar is so itchy and uncomfortable, I'll be unravelling it and starting over. It is extraordinarily warm, for fingering weight yarn (LB1878), so I decided to wait on the deconstruction till after winter was over. I actually finished it before Christmas 2010.

As you can see, there were some issues.

Aside from a botched collar, there are many patterning errors. I might have left it alone despite the patterning flaws, but the collar is so itchy and uncomfortable, I'll be unravelling it and starting over. It is extraordinarily warm, for fingering weight yarn (LB1878), so I decided to wait on the deconstruction till after winter was over. I actually finished it before Christmas 2010.

Labels:

knitting

Subscribe to:

Posts (Atom)